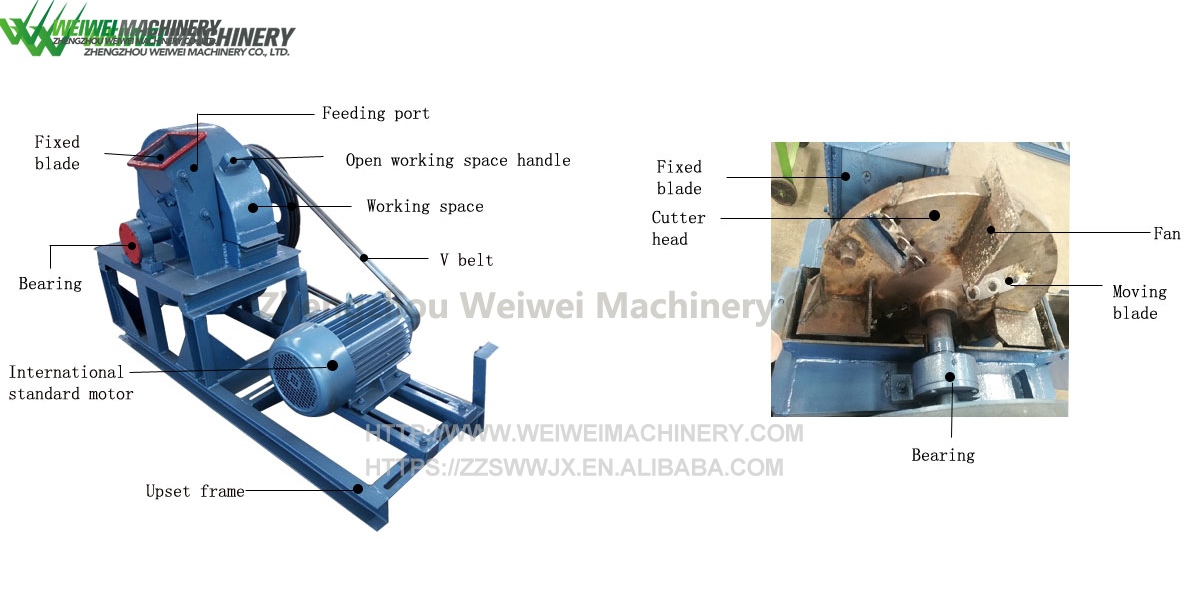

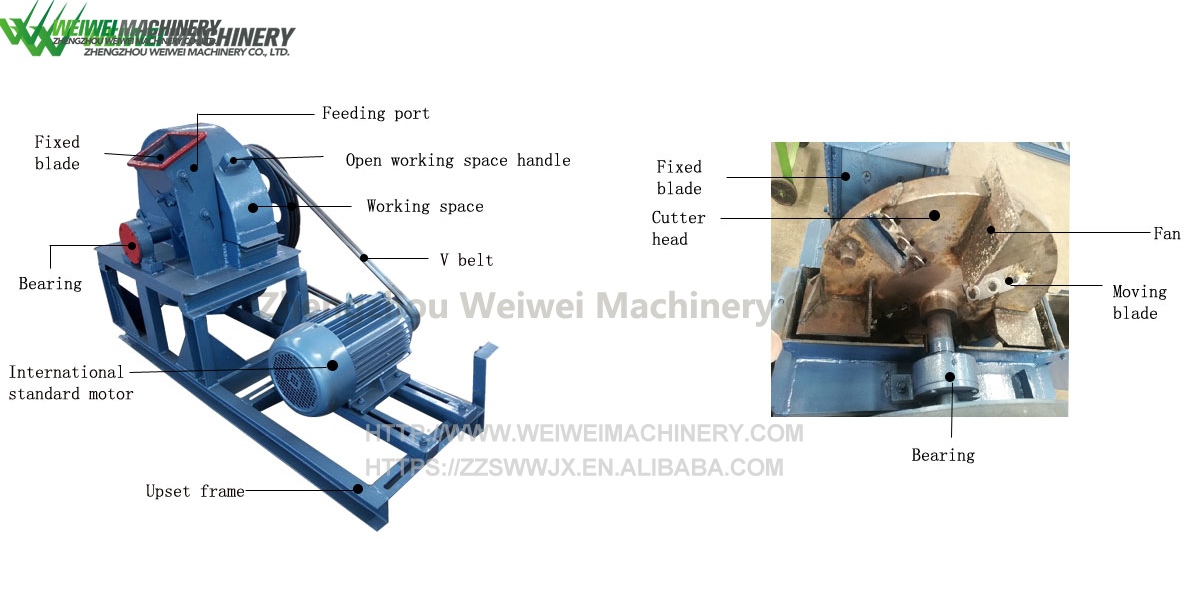

Working Principle

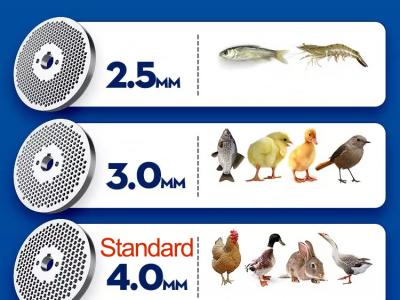

The raw material enters the feed inlet, the blade, cutting into the crushing chamber, and then generated by the built-in fan blade of the wind to send particles to the outlet. The size is determined by the particle adjustment of blade length and the size of mesh size, to adapt to the various needs.

The main part of the machine is through the dynamic balancing equipment, each machine's weight error range is less than 15g, so that the machine can run smoothly,reduce noise, improve production efficiency, prolong the service cycle, low cost, high yield, is the mature technology of wood processing machinery .

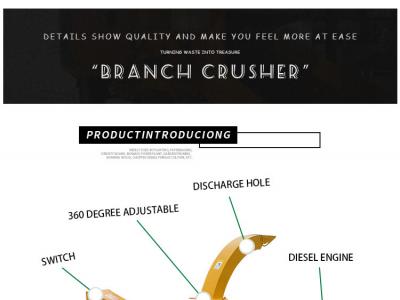

1.The feeding port adopts automatic feeding device

The feeding port adopts automatic feeding device, the wood timber go through feeding port into machine, the wood be cut by blade(cutter), then be blow out of the machine by fan blade of cutters, then users can get uniform wood shavings.

2.Cutter head

The cutter is composed of thick steel plate and changed the original fragile, increase the service life of the machine, fan design is enhanced in the machine running speed of wood, wood from the machine speed and easy to sieve out the whole cutter head, smooth operation, regrinding the wood.

3.The cutting blade adopts high quality alloy cutting tools. The cutters are hard, wear resistant, cutting sharp, difficult to rust, corrosion resistant, and the service life is longer than the general steel cutting tools, the output of wood crusher is larger .

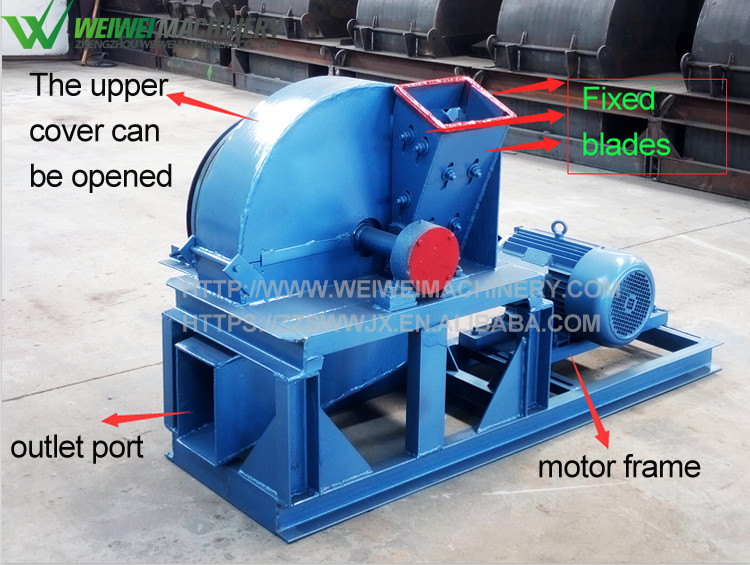

4.Extensive feed port and fixed blades

The machine adopt extensive feed port and it is convenience for raw materials, Meanwhile,it also increasing the yield. The thickened fixed blades are made of steel and installed on the inlet hopper, unique design, fixed knife working with cutter to complete wood shavings process 。