Applications

Applications

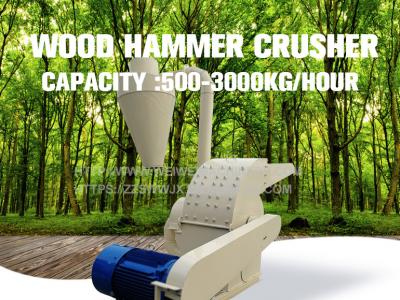

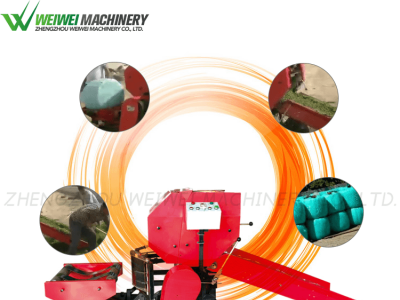

This multi-function grinder combines the advantages of hammer wood grinder and blade disc wood grinder.

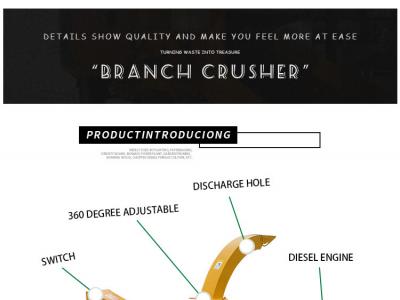

The material not only to crush logs, but also to crush raw materials.

Such as scrap, branches, bark, leaves, etc. Roots, branches, bark, peanut shells, corncob, corn stalks, peanut flesh, melon flesh, straw, wheat straw and other materials and logs are crushed into sawdust or chips,

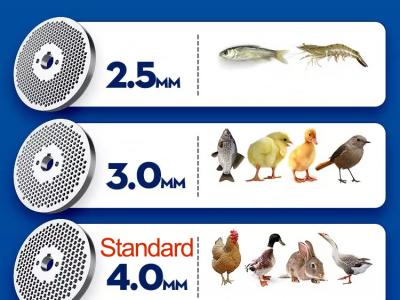

According to the different size of screen mesh,the machine can cutting and grinding different effect.Minimum effects size reachability 0.5mm.

Adding a cyclone collector can reduce the dust pollution, add the aggregate bag, and more conveniently collect the finished product of the user.

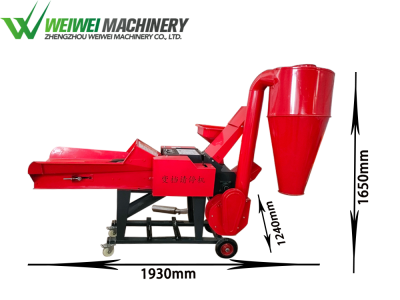

Working Principle

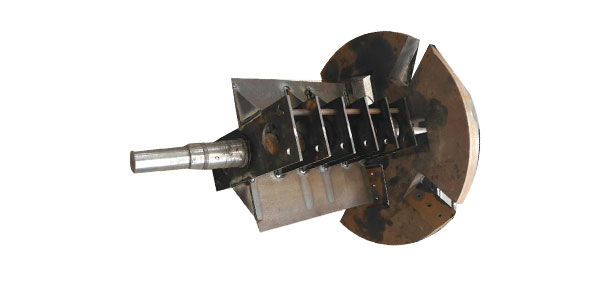

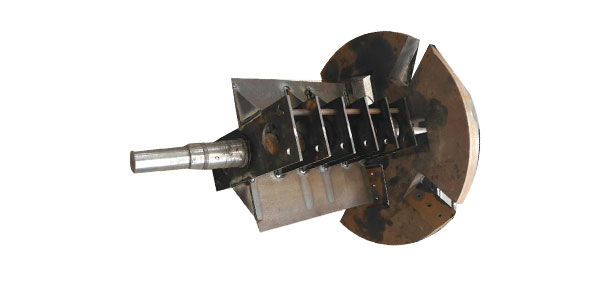

The blade cutting and high speed airflow impact crushing, collision of double functions, and can simultaneously complete micro material sorting process. In the blade cutting and grinding process, the rotor generates a high speed airflow, with the blade cutting direction of rotation, the material in the air flow speed, and make the material and under repeated impact crushing, accelerated material crushing rate .

Our factory is specialized in multi-functional timber mill, multi-functional timber mill set section, smash into one machine, the processing of Chinese fir, pine Yang wood, bamboo, corn chips, sorghum stalk, straw like fibrous material is crushed. Commonly used in charcoal factory, artificial board factory, bio power plant, paper mill, sawmill, feed factory letinous edodes farm, edible fungus base, grinding and other green landscape engineering of the factory.

1.The cutting blade adopts high quality alloy cutting tools. The cutters are hard, wear resistant, cutting sharp, difficult to rust, corrosion resistant, and the service life is longer than the general steel cutting tools, the output of wood crusher is larger .

2.Cleading

The cleading is added to the working room, and the function of the lining board is to crush the crushed wood through two times of grinding, thereby increasing the crushing efficiency of the wood and increasing the output

3.Hammer by carbon steel can be made of wood for multiple impact crushing, and then improve the broken rate, and can use both sides of the hammer, ones side broken, the user can replace the hammer hammer, but can change at the same position, can not be exchanged, so as not to affect the dynamic balance of the machine, double-sided use reduce the use cost.

4.The main part of the machine

The main part of the machine is through the dynamic balancing equipment, each machine's weight error range is less than 15g, so that the machine can run smoothly,reduce noise, improve production efficiency, prolong the service cycle, low cost, high yield, is the mature technology of wood processing machinery