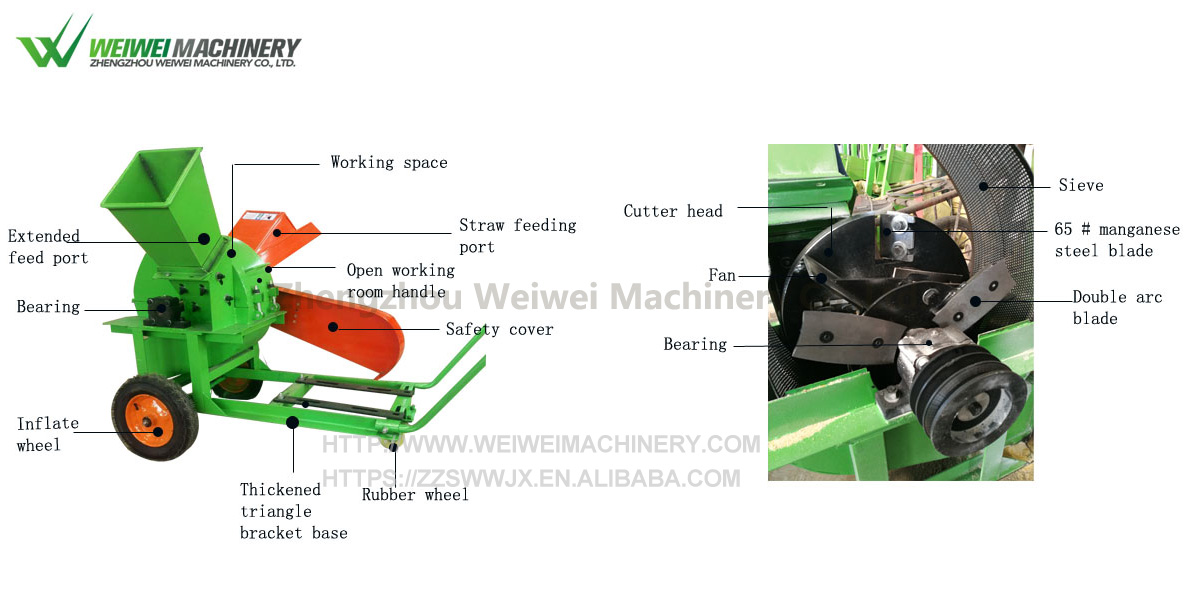

Working Principle

The blade cutting and high speed airflow impact crushing, collision of double functions, and can simultaneously complete small size material sorting process. In the blade cutting and grinding process, the rotor generates a high speed airflow, with the blade cutting direction of rotation, the material in the air flow , and make the material under repeated impact crushing, accelerated material crushing rate.

Machine instructions:

1, the power supply is switched on, see turn is correct.

2, When need to change the cutter, cutter blade out of plane 2 - 4mm, and then tighten the bolts. If the pressure bolt thread wear, should be replaced immediately, and with sliding knife wheel nut.

3, change the knife flexibility, extension must be the same length.

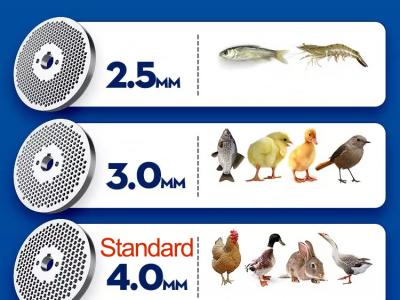

knife adjustable knife, length of particles to reach the ideal, change the different diameter of the sieve.

5, no entrainment stone and wood nails into the machine, to prevent broken knife and inner parts.

6, check the hammer bolts loosening, immediately hammer and bolt fastening, severe wear that should be replaced.

7, The angle of the moving blades is 28°-30°, the blades can’t be worn to convex, convex steel blade will lead to detachment or removing the part of steel.

8, Regular use of the machine should check whether the lack of bearing grease. Should be 3 - 4 hours filling butter a grease is not too much.

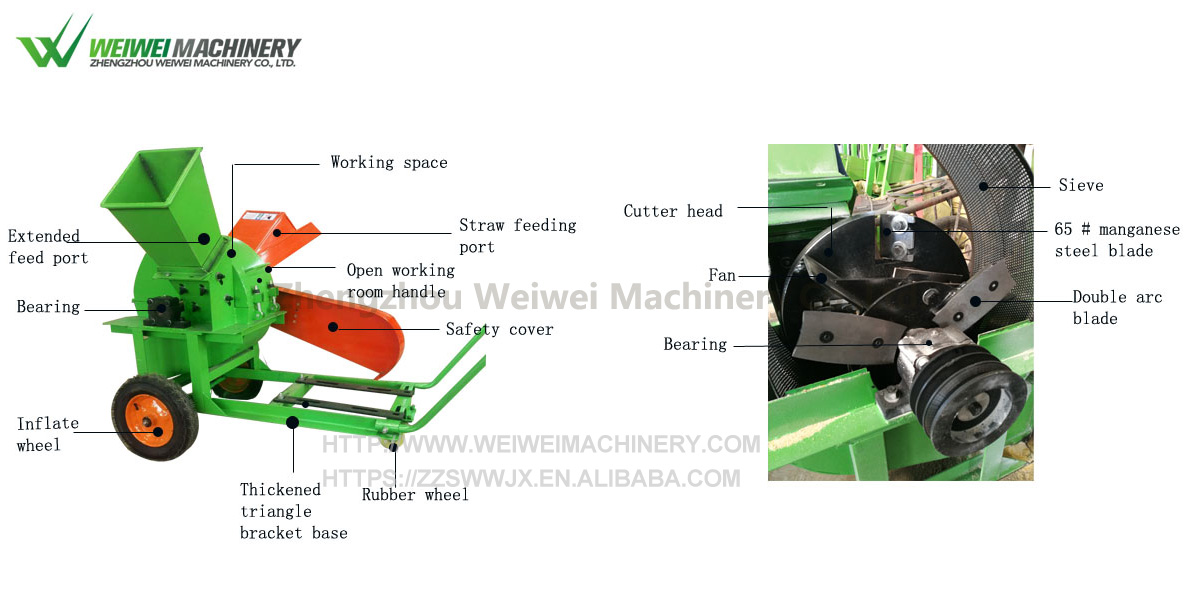

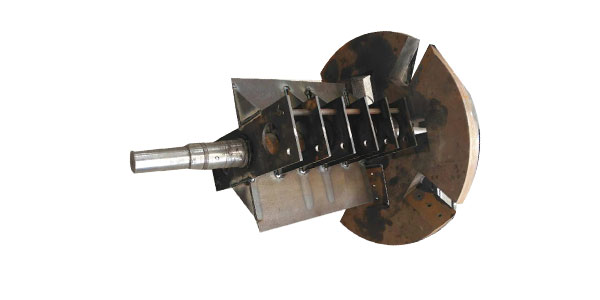

1.Moving blade

The cutting blade adopts high quality alloy cutting tools. The cutters are hard, wear resistant, cutting sharp, difficult to rust, corrosion resistant, and the service life is longer than the general steel cutting tools, the output of wood crusher is larger .

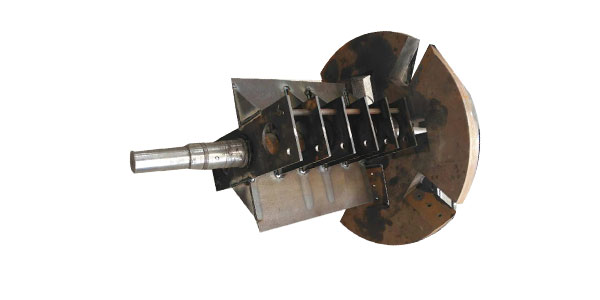

2.The main part of the machine

The main part of the machine is through the dynamic balancing equipment, each machine's weight error range is less than 15g, so that the machine can run smoothly,reduce noise, improve production efficiency, prolong the service cycle, low cost, high yield, is the mature technology of wood processing machinery

3.Cutter head

The cutter is composed of thick steel plate and changed the original fragile, increase the service life of the machine, fan design is enhanced in the machine running speed of wood, wood from the machine speed and easy to sieve out the whole cutter head, smooth operation, regrinding.

4.Hammer blade

Hammer is made of carbon structural steel ,multiple impact crushing the wood , then improve the broken rate, user can use both sides of the hammer, one side broken, the user can replace the hammer hammer, but can change at the same position, can not be exchanged, so as not to affect the dynamic balance of the machine, double-sided use reduce the use cost.