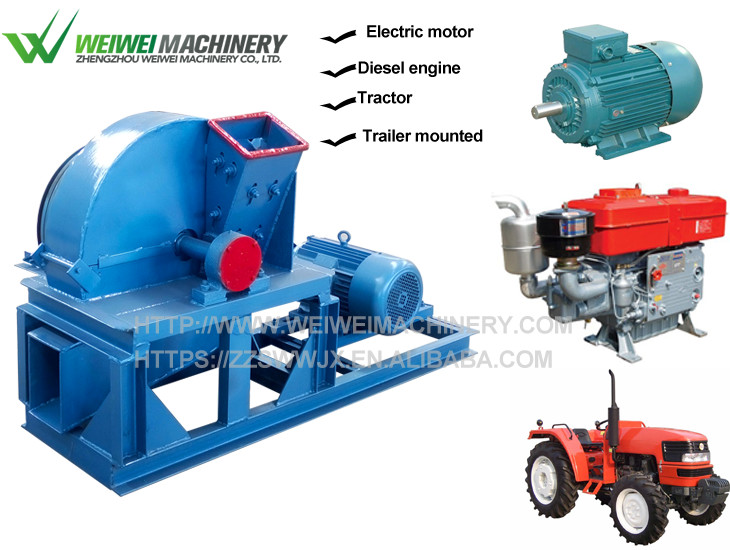

The shavings machine is an automatic wood chip crushing machine, mainly made from logs (branches), twigs (branches), boards, furniture offcuts etc., which are automatically cut and processed into flaky shavings. The finished product can be used for animal deodorisation beds (pet beds), animal washers, flower growing, fungal cultivation, chipboard (plywood), special packaging, paper mills, etc.

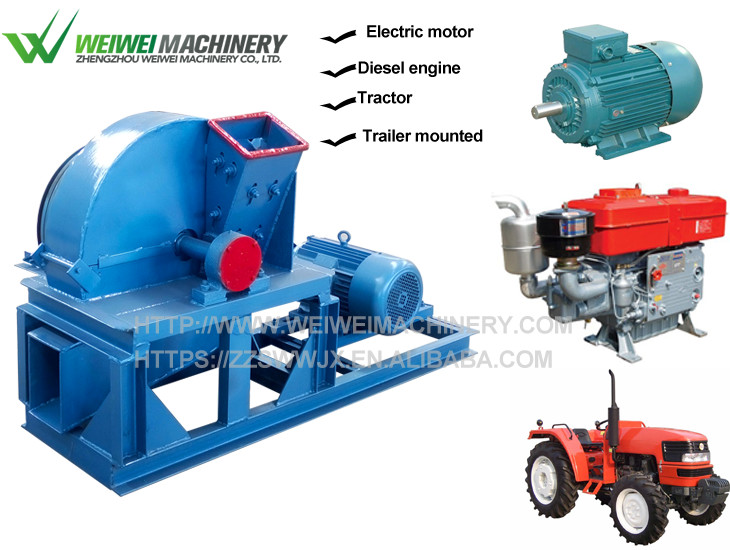

Select an electric motor (diesel) as the power source, connect the power unit, make sure the machine is running properly, insert the logs from the input port and complete the cut with the combined action of the fixed and fast knives. - Move the cutter head and blow the chips away with the wind from the built-in fan.

The machine is a new type of woodworking machinery and equipment, mainly used for mass production of uniform thickness flakes, is a kind of automatic shaving machine (wood shaving machine) can be sticks, twigs, branches and logs can be used as processing, shaving machine produced wood furniture factory and produced wood is the same. This machine adopts automatic feeding device, compared with the traditional simple operation, but also increase the particle produced speed, saves manpower and time

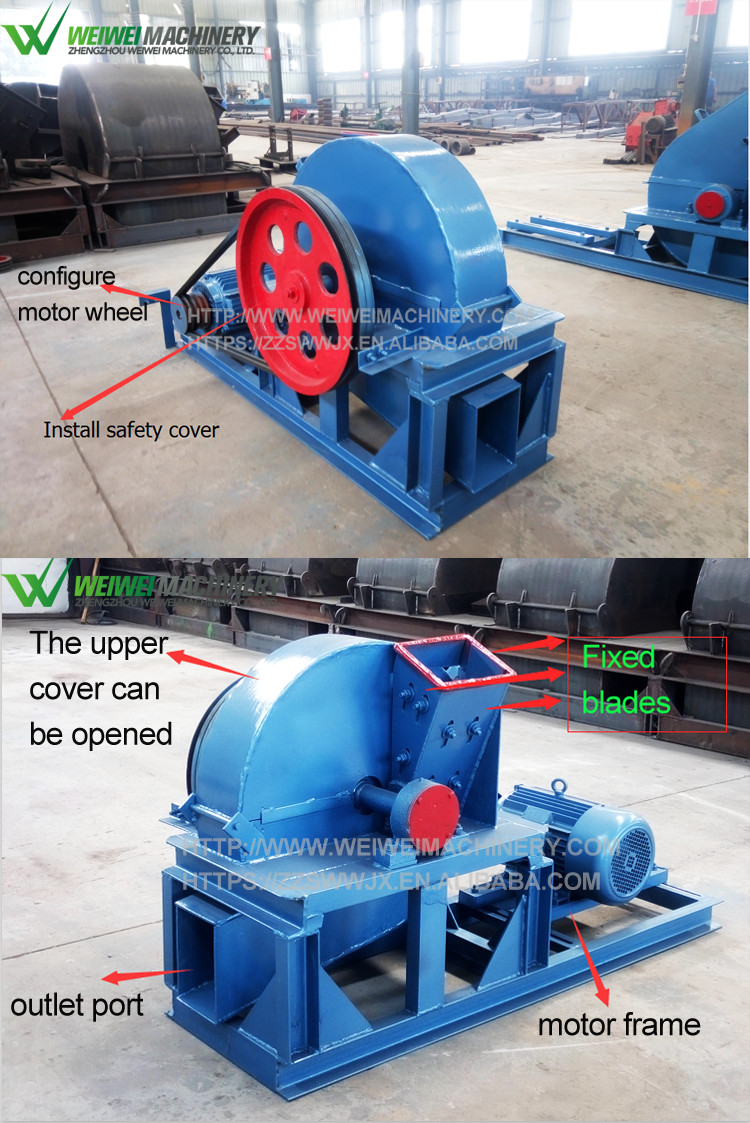

The feeding port adopts automatic feeding device

The feeding port adopts automatic feeding device, the wood timber go through feeding port into machine, the wood be cut by blade(cutter), then be blow out of the machine by fan blade of cutters, then users can get uniform wood shavings.

Cutter head

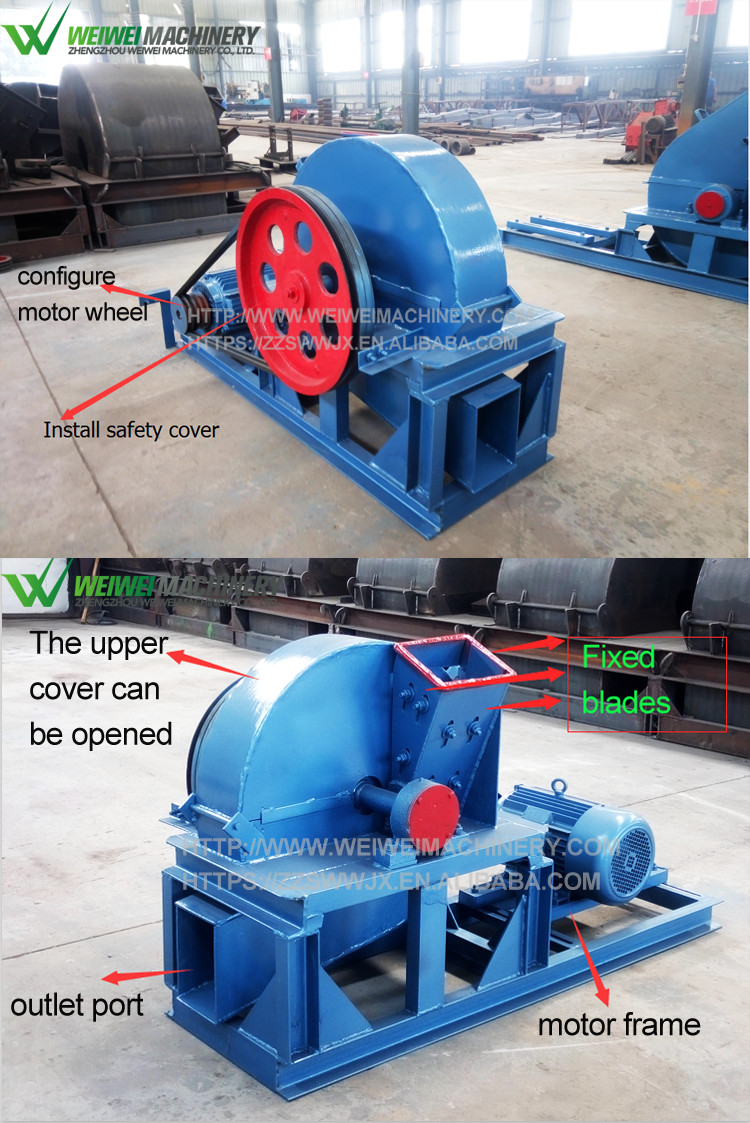

The cutter is composed of thick steel plate and changed the original fragile, increase the service life of the machine, fan design is enhanced in the machine running speed of wood, wood from the machine speed and easy to sieve out the whole cutter head, smooth operation, regrinding the wood

Alloy knives

The cutting blade adopts high quality alloy cutting tools. The cutters are hard, wear resistant, cutting sharp, difficult to rust, corrosion resistant, and the service life is longer than the general steel cutting tools, the output of wood crusher is larger .

Extensive feed port and fixed blades

The machine adopt extensive feed port and it is convenience for raw materials, Meanwhile,it also increasing the yield. The thickened fixed blades are made of steel and installed on the inlet hopper, unique design, fixed knife working with cutter to complete wood shavings process

The main part of the machine is through the dynamic balancing equipment, each machine's weight error range is less than 15g, so that the machine can run smoothly,reduce noise, improve production efficiency, prolong the service cycle, low cost, high yield, is the mature technology of wood processing machinery

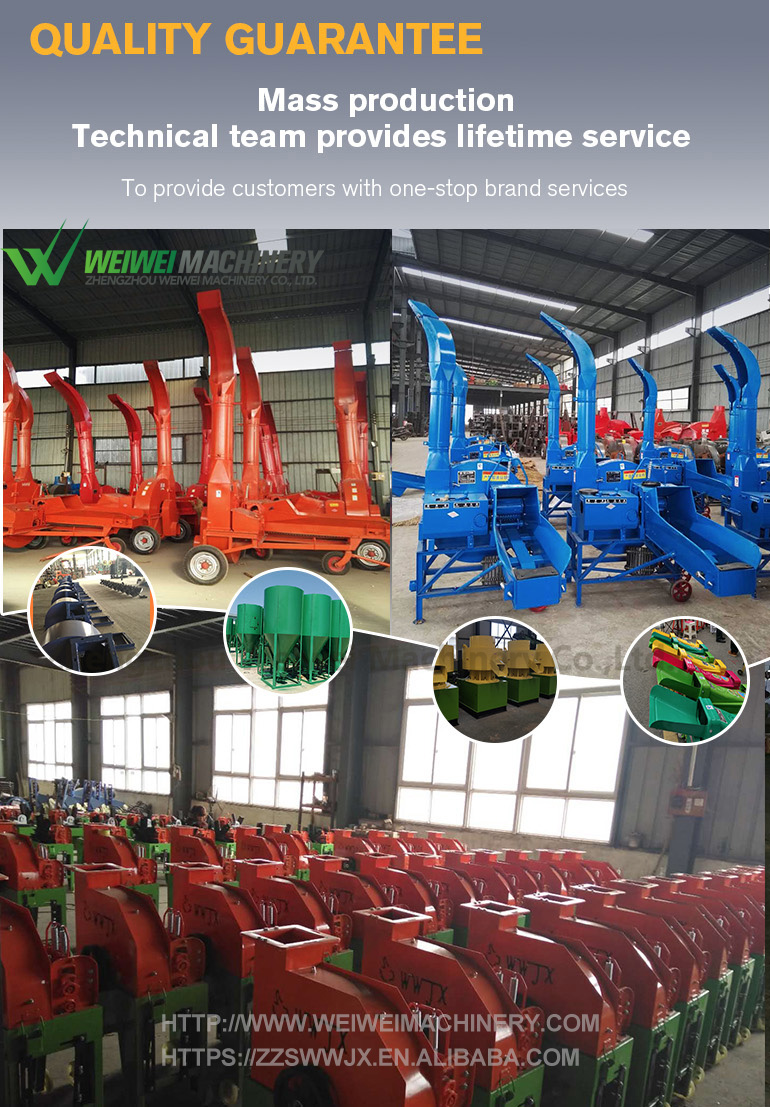

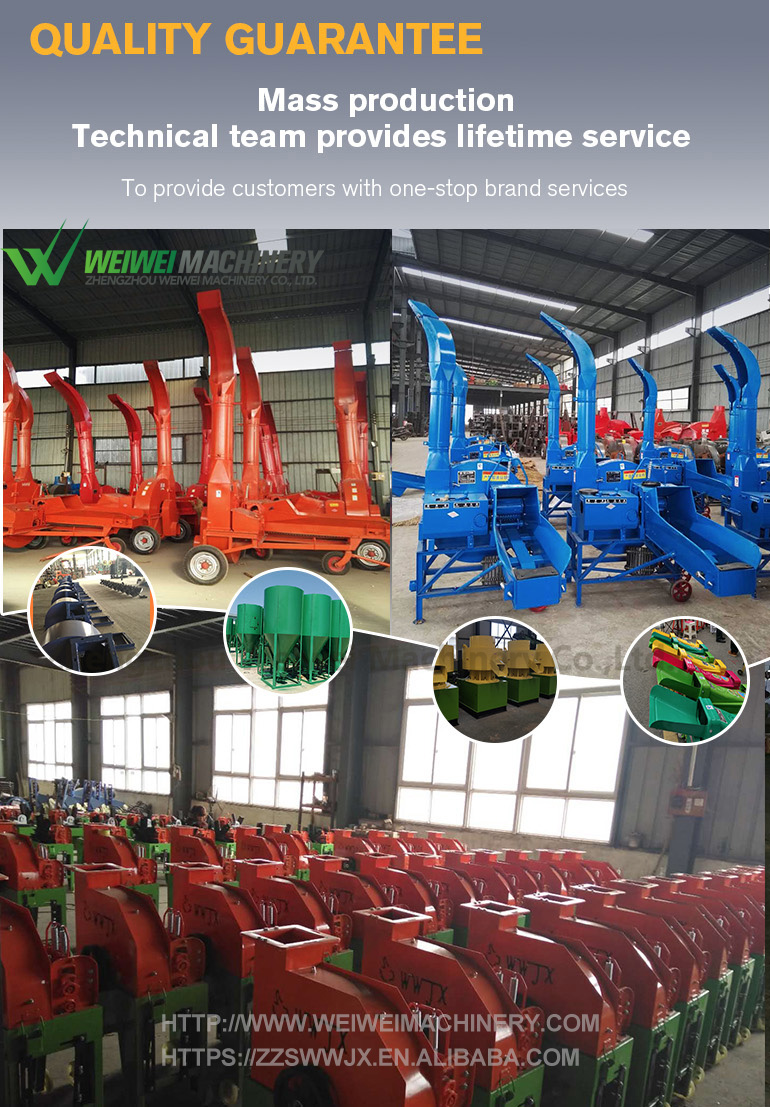

Our company is located in the western suburbs of Zhengzhou City, the capital of Henan Province, 3 km north of Xingyang Station on the Kai-Luo Expressway, and was established in 1980 with an area of 10,000 square meters and an annual production capacity of 40,000 to 50,000 units. The company mainly produces: 9ZP series kushiage, 9ZF series grass grinder, 9FQ series feed grinder, MFJ series wood grinder, MBJ series wood chipper, MPJ series wood chipper, DJM series multi-functional wood grinder, 9YF series baler, corn thresher, corn ripper, peanut sheller, biomass pellet machine, supporting power motor, etc., and all kinds of The company has a wide range of agricultural, garden and livestock breeding machinery and equipment, including feed processing machinery. The company always pursues excellence, with high quality staff, strict quality assurance system and optimal management of the entire production process, to ensure our "high-quality projects". The perfect after-sales service system allows you to have no worries.