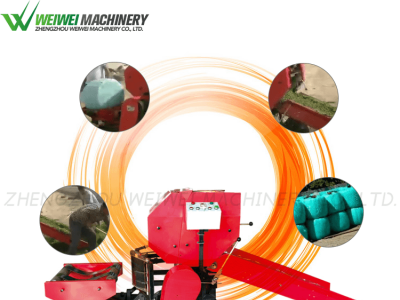

Crushing wood shouldn't give you a headache. With the right machine, the process should be very smooth and you can get the desired results without any effort. When choosing the right wood shredder, make sure that its operation is easy to control and does not require complex training. One feature to look out for is the ability to reverse the direction of operation. A good wood chipper has a built-in automatic reversing controller. This senses congestion and changes direction to clear the obstacle within a predetermined time. This has the added benefit of providing an exit for material that cannot be shredded for shredding.

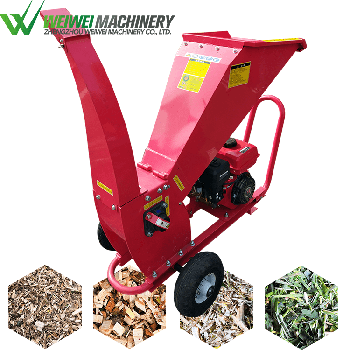

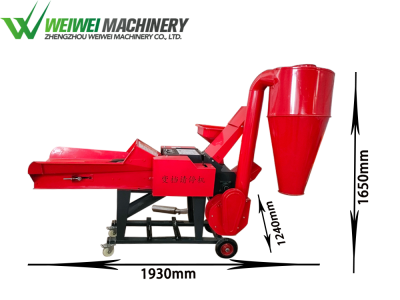

There are two basic questions to ask here:How big and how much material are you handling? These two factors will play an important role in your choice of machine, as both size and capacity need to meet demand. Overloading a wood chipper can damage its performance and service life. Conversely, underloading the machine will not cause immediate harm, but can lead to problems with the machine. Another factor you need to consider is whether the size of your load will change? If so, you will need a shredder that can be adjusted to the load you are feeding at the time.

With any wood shredder, it is important to note that they require some maintenance. The size and type of shredder you choose will determine how much maintenance it will require to work properly. Having said that, however, there are many 'low maintenance' shredders available that only require regular lubrication and oil changes. Suppose you want to find a solution that is easy to maintain. You can contact the technical team at Pujia Intelligent Environmental Protection and we can recommend some suitable wood shredders. Jay's wood shredders are low speed, high torque, high capacity, easy to maintain, easy to use and can effectively break through every large piece of wood at once.