Ring die pellet machine is a large-capacity and multi-functional pellet machine, which can be used to manufacture feed pellets, as well as organic fertilizer pellets and biomass pellets.

When manufacturing the feed pellet machine, the ring die pellet machine is directly pressed into pellets from the crushed materials of soybean, soybean meal, rice husk, corn, bran, forage, straw, etc. It is widely used in large, medium and small aquaculture, grain and feed processing. Factories, livestock farms, poultry farms, especially suitable for scenarios with large demand and output

When making organic fertilizer, various soybean meal, bran, sawdust, forage, crushed straw, animal manure, etc. are used as raw materials to be pressed into organic fertilizer, which can be widely used in environmental protection equipment for agricultural planting and returning to fields.

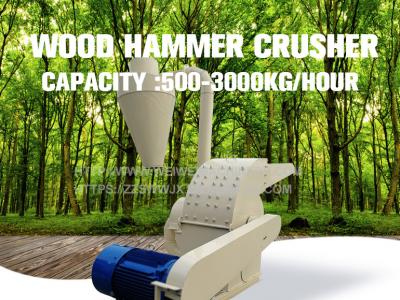

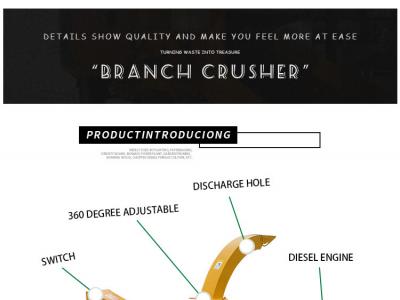

Wood chips, sawdust, straw, peanut shells, cotton stalks, shavings, etc. can also be used. The best material size is 3-5mm.

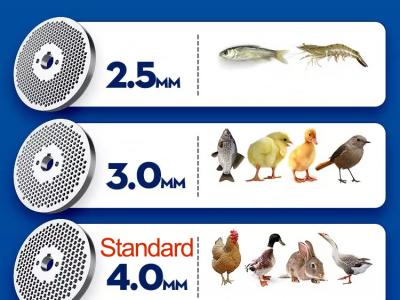

Manufacturing particle diameter: 2.5, 3, 4, 5, 6mm

working principle

The material enters the rotating feed hopper and the mold cavity through the feeding port. Due to the action of centrifugal force, the material is continuously thrown to the inner wall of the die to form a uniform annular material layer, and the annular material layer is brought into the ring. On the contact surface of the die and the pressing roller, the cylindrical particles are extruded from the die hole through the extrusion action of the ring die and the pressing roller, and are cut into particles of uniform length by the cutter fixed on the casing

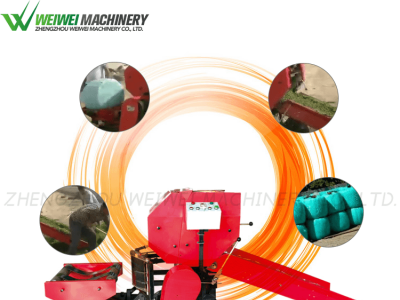

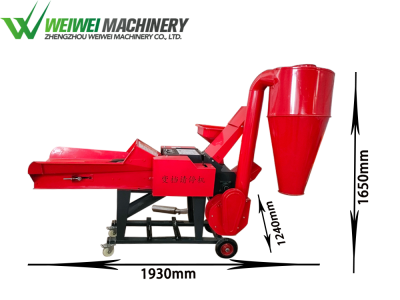

1.Structure: The granulator is mainly composed of a frame, a pressing roller, a ring die, a main shaft, an eccentric shaft, a motor, a belt drive, etc.

2.The frame is mainly a device supporting the entire transmission part and fixing the main shaft. The motor is installed on the channel steel of the frame, and the tightness of the belt can be adjusted through the sliding hole on the motor plate. The large pulley cover is fixed on the frame, which not only protects the safety of the large pulley, but also supports the feeding cover.

3.It is mainly composed of motor, large pulley, motor wheel, bearing gland, ring die, and feeding basin. The motor wheel drives the large pulley to rotate through the belt, and the large pulley is supported on the main shaft which is firmly fixed to the frame through two tapered roller bearings. The axial positioning of the large pulley is realized by the two bearing caps. One end of the large pulley is used to fasten the ring die with 6 M12 bolts, so that the ring die and the large pulley rotate together. The feed basin is installed on the end face of the ring die and rotates with the ring die, and the material enters the ring die through the feed basin