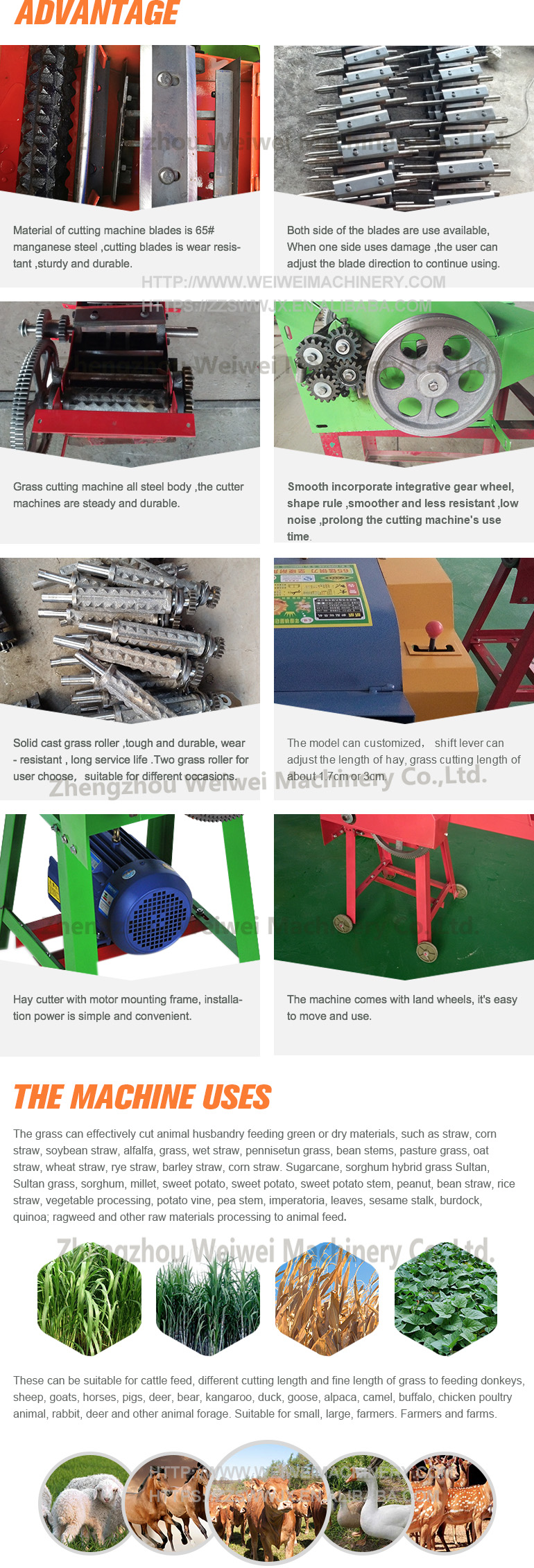

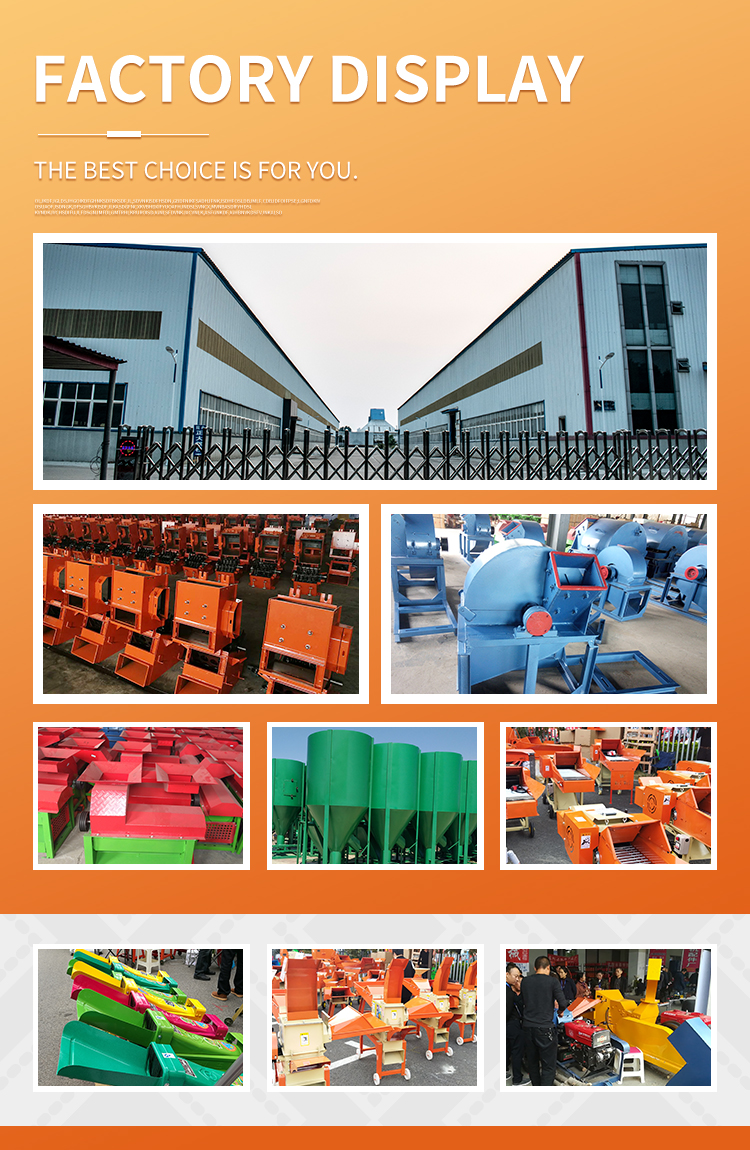

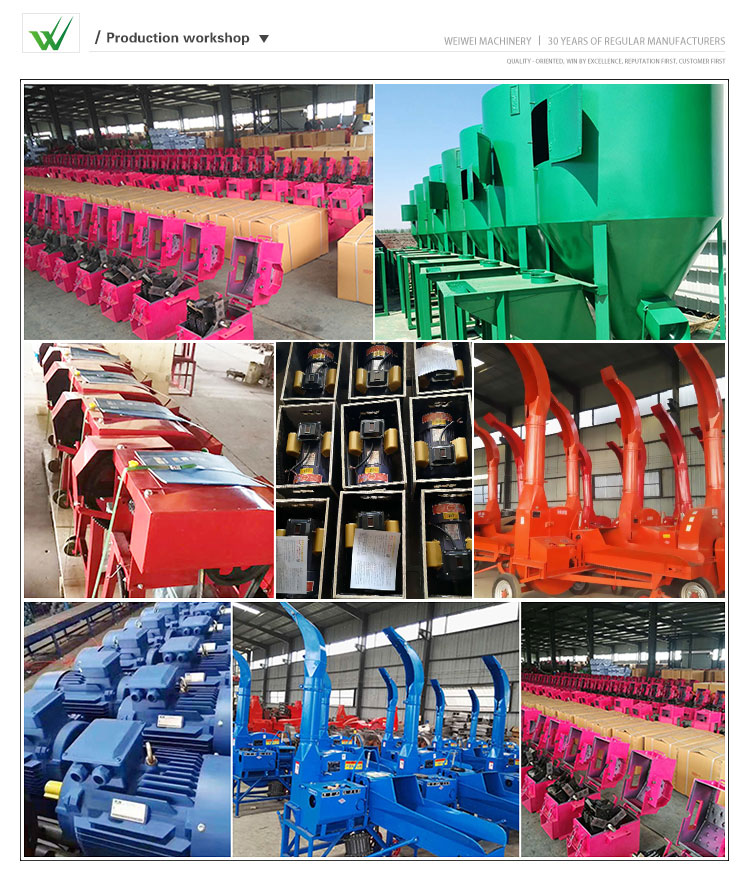

The guillotine is mainly used for guillotining all kinds of dry and wet crop straw and pasture grass, such as maize straw and rice straw. It is used for raising cattle, sheep, horses, deer and other animals, and is suitable for pasture and professional farmers. Weiwei agricultural machinery has established more than 200 sales outlets in more than 30 provinces, cities and municipalities across China. Our products are exported to more than 40 countries and regions such as USA, Pakistan, Romania, Malaysia, Columbia, etc. and have won a good reputation and good feedback from the market.

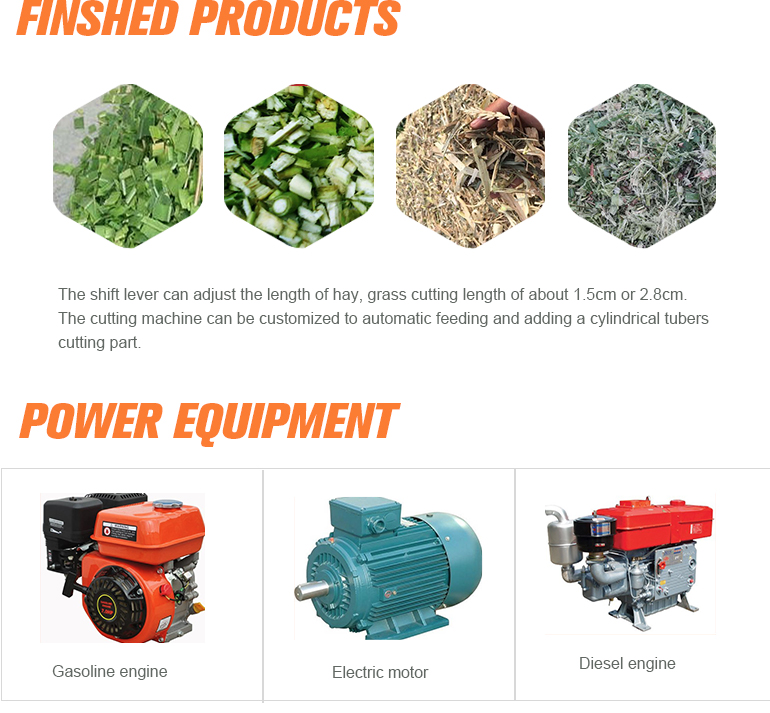

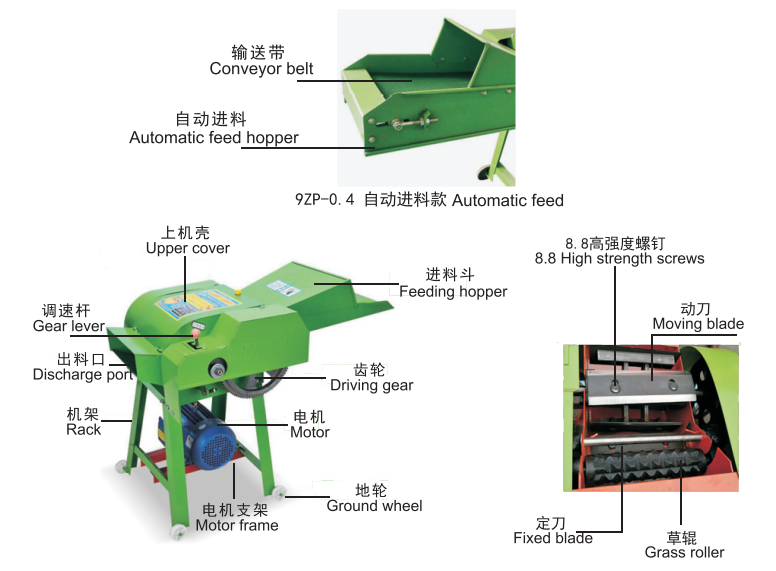

The electric motor is used as auxiliary power. The power is transferred to the spindle and the gears at the other end of the spindle transmit the reduced power to the rollers via the gearbox and universal joints. The grass is then clamped by the rollers, held at a constant speed in the gate cutting mechanism, shredded by the high-speed rotating cutter and discharged from the machine through the outlet.

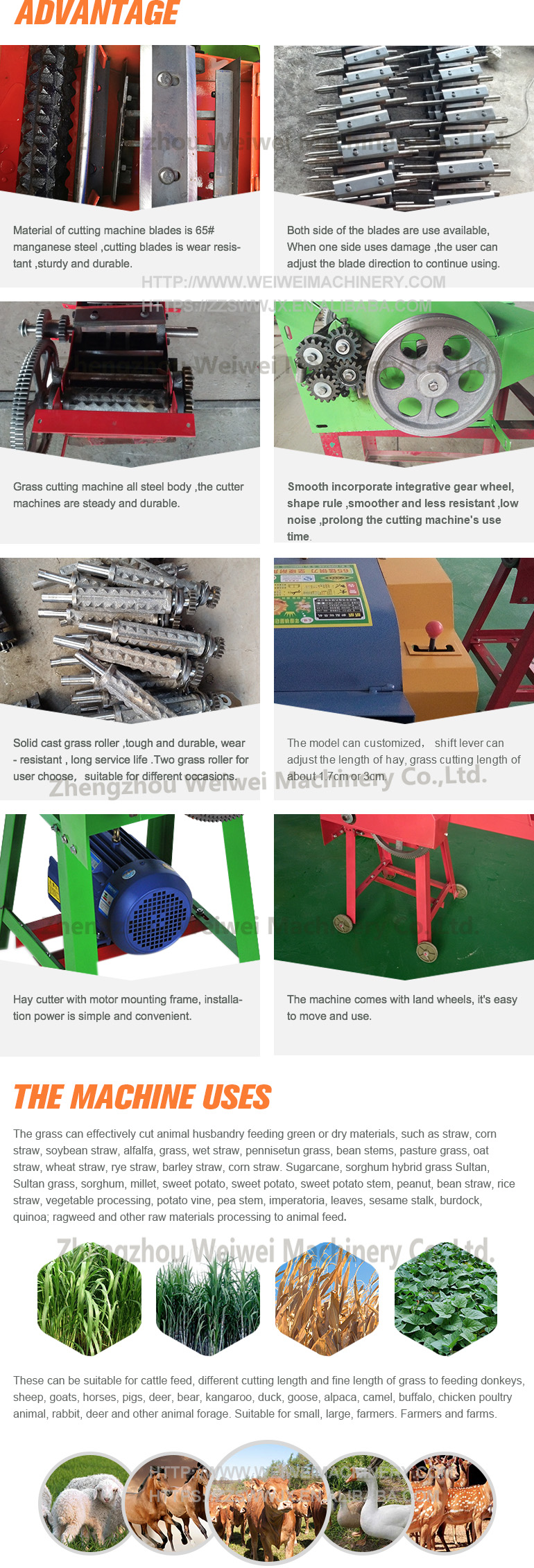

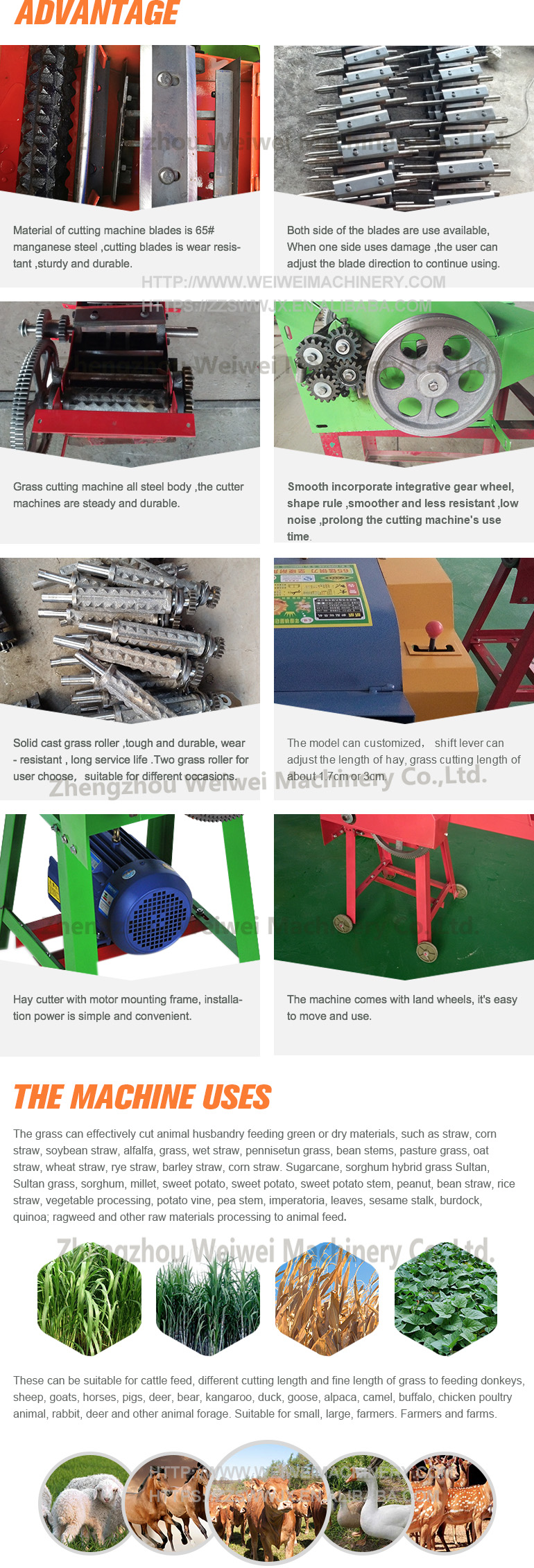

1.The casing is welded by thickened steel plates, with long service life, stable body, and the thickness of the upper casing is about 3 mm.

2.The coating adopts the baking paint process, with bright colors, good durability, corrosion resistance and durability.

3.The feeding hopper is heightened, widened and thickened, which can be fully fed and improve production efficiency.

The thickness of the feeding hopper is 1 mm, the others are 0.8 mm, it is durable and has a long use time.

The feeding port is arc-shaped, and the outer edge is rolled up to prevent scratches

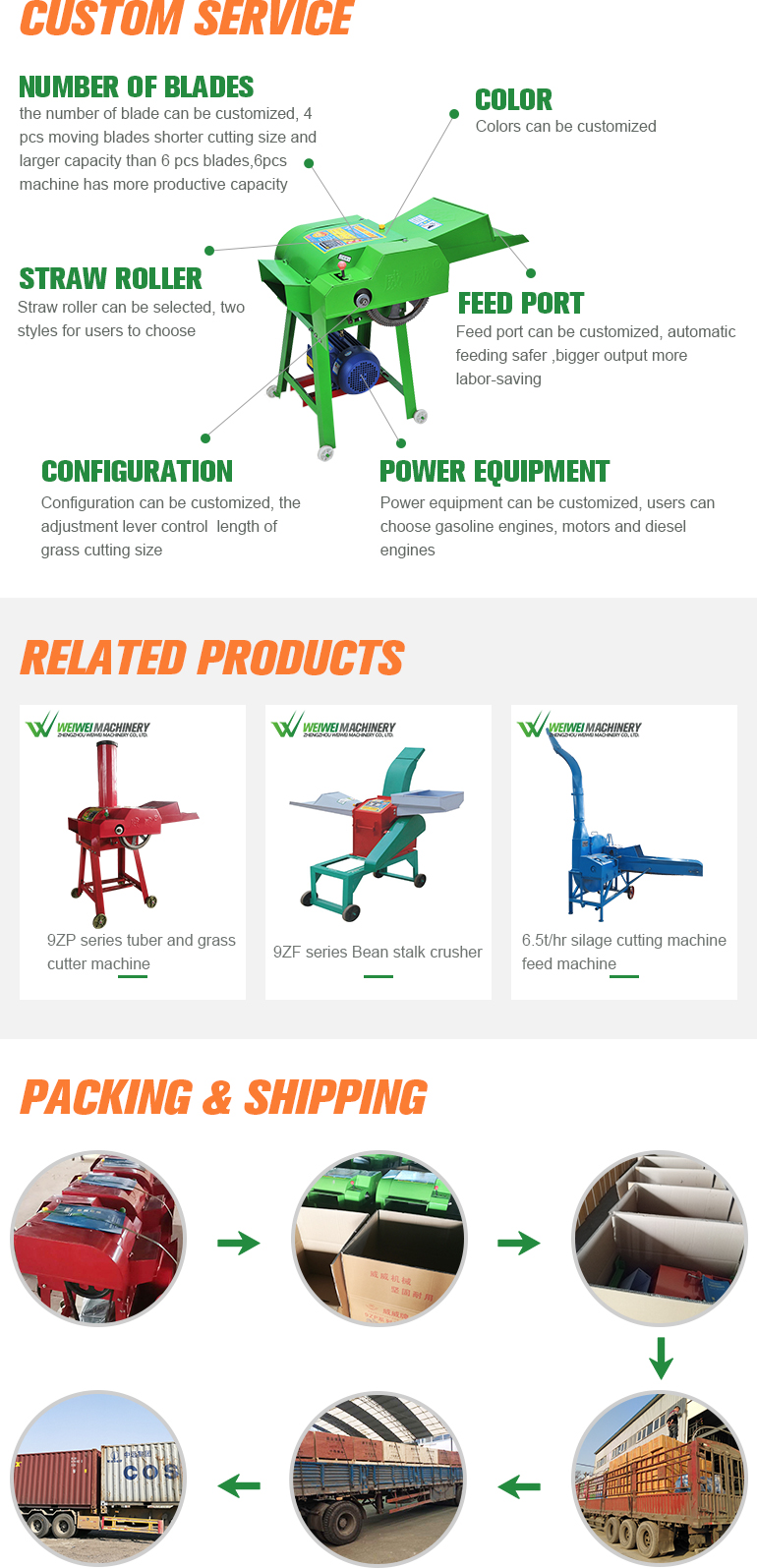

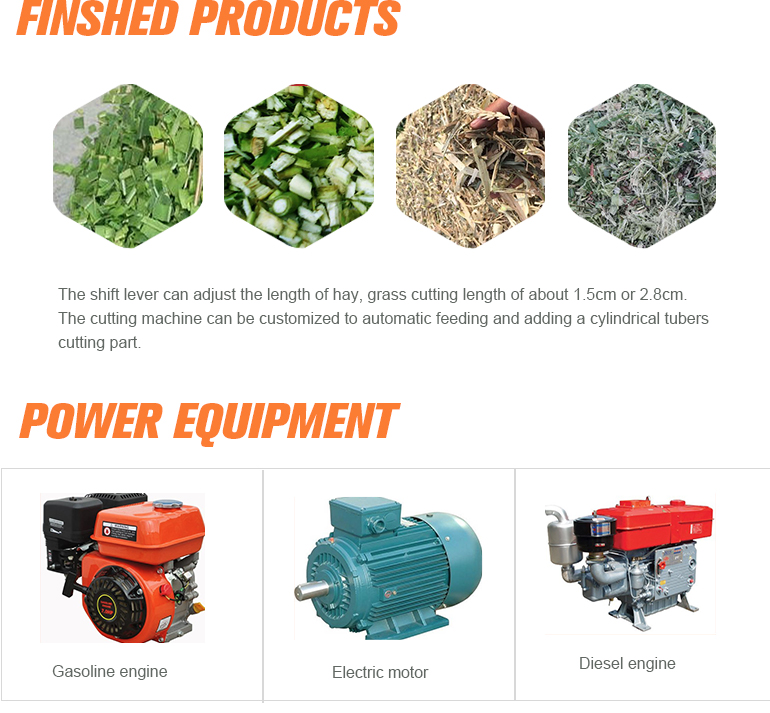

4.Motor models, gasoline and diesel models are available upon request

5.The cutter head is welded by thickened steel plate, which is sturdy and durable. Increase inertia during operation, save power and high efficiency. The blade is widened and thickened, made of 65 manganese steel. After special heat treatment, it has the characteristics of sharp wear resistance and long service life. When the blade is assembled, the movable knife and the fixed knife maintain a certain slope, thereby reducing the cutting resistance and improving the efficiency of cutting grass. Productivity.

6.There are two types of grass pressing rollers to choose from. The corrugated grass pressing roller combs and pushes the forage, and the horizontal grass pressing roller can more smoothly compact the grass. There are two kinds of materials: pig iron and wrought iron, and more price options. The grass pressing roller is tough and durable, wear-resistant and corrosion-resistant, and has a long service life.

7.Gears are smooth one-piece gears machined from a flat surface and a hobbing. The gear is more compact, the shape is regular, smooth and wear-resistant, the power transmission is smoother, the noise is low, and the service time of the cutting machine is prolonged

8.The bearing chamber is made of cast iron, which is not easy to break. Most of the market is stamped from iron sheets.

Self-aligning bearings inside increase stability and balance the fuselage

Founded in 1980, the company has a history of 32 years. It covers an area of more than 10,000 square meters. It is an industry and trade company integrating scientific research, design, manufacturing and sales. The technical research and development and promotion of equipment can be modified and changed according to customer needs.