weiwei Getreide- und Weideschneid- und -häckselmaschinen für landwirtschaftliche Betriebe, Viehzüchter, Landwirte, Futtermittelverarbeitungsbetriebe usw. zum Schneiden und Häckseln von Weide, Stroh, Maisstängeln und anderen Pflanzen.

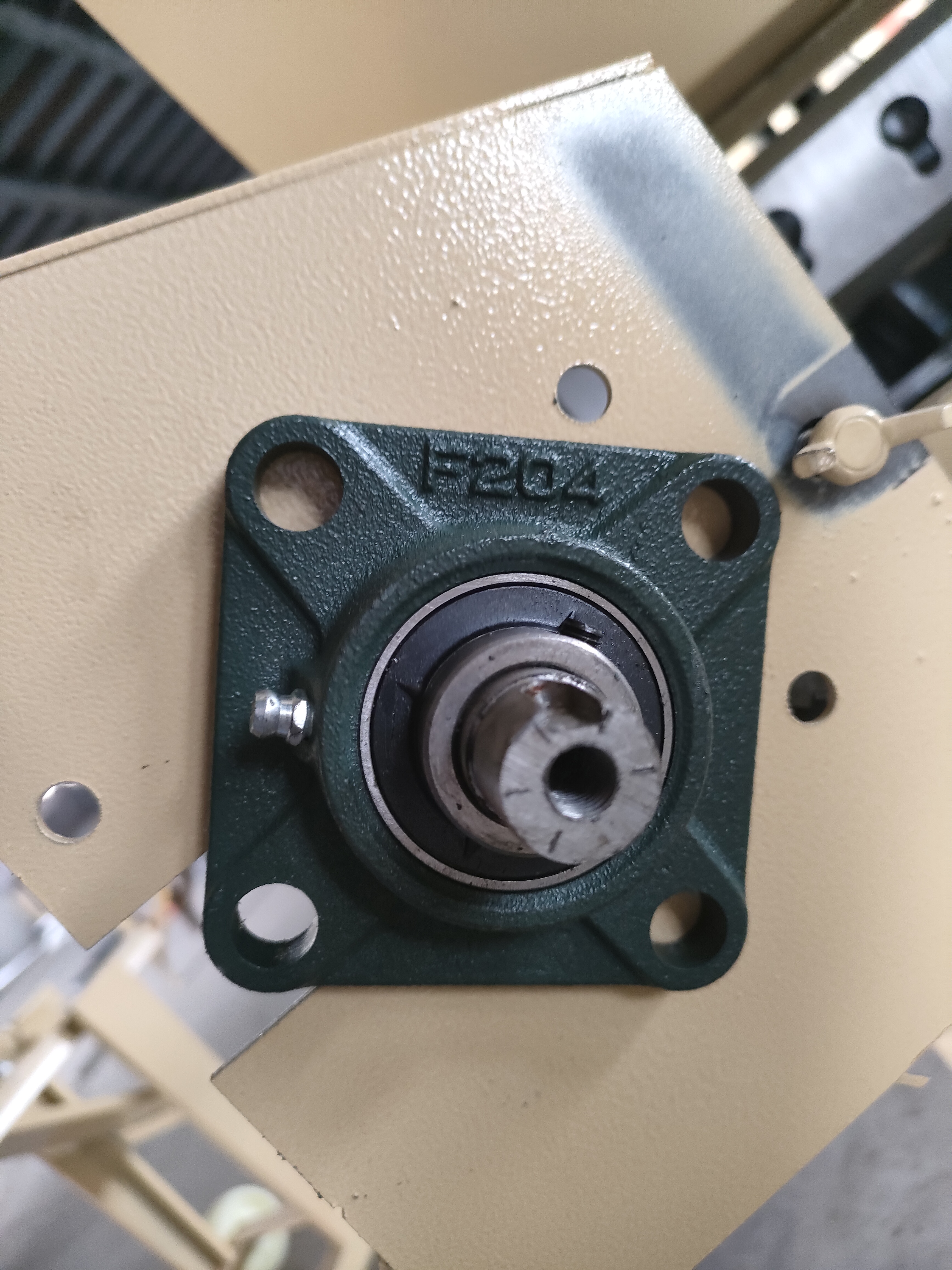

a. Feeding device: mainly composed of feeding hopper, feeding roller, fixed blade, fixed knife support seat, etc.

b. Guillotine cutting and throwing device: mainly composed of moving knife, knife plate, locking screw, etc.

c. Walking device: mainly by the ground casters or walking rubber wheels (can be equipped with traction frame) and other components

d. Protective device consists of machine protective cover, etc.

| Model |

9zp-0.4 |

9zp-0.4A |

9ZP-0.4B |

9ZP-0.4V |

9ZP-0.4AC |

| Matching power(kw) |

2.2-3 |

2.2-3 |

2.2-3 |

2.2-3 |

2.2-3 |

| Motor speed(r/min) |

2800 |

2800 |

2800 |

2800 |

2800 |

| Spindle speed(r/min) |

950 |

950 |

950 |

950 |

950 |

| Weight of main machine(kg) |

50 |

53 |

58 |

65 |

60 |

| Output(kg/h) |

400-1200 |

400-1200 |

400-1200 |

400-1200 |

400-1200 |

| External dimensions(mm) |

1085*470*850 |

1085*470*850 |

1055*550*875 |

1085*470*1325 |

1085*470*875 |

| Number of blades(pcs) |

2,3,4 |

2,3,4 |

6 |

4/6 |

4/6 |

The guillotine is powered by an electric motor (diesel or petrol engine). The material to be processed enters between the upper and lower pressure rollers, is clamped by the upper and lower rollers and sent to the guillotine device at a certain speed, and is chopped by the high-speed rotating knife (or crushed again by the triangular blade) and then thrown out of the machine through the outlet.

1. After receiving the goods, please unpack the machine and check the accessories (feeding hopper, frame, ground wheels, motor pulley, motor frame, grinding wheel, screw bag, belt, etc.)

2. Put the machine upside down on a flat ground, fix the frame and tighten the screws.

3. Install the ground wheel at the designated position, and use the pin to fix the wheel

4. Install the motor frame at the specified position (not fixed for now)

5. Turn the machine to standing state

6. Remove the cover and the screws securing the cover

7. Install the feed hopper according to the specified position, fix the feed hopper, and tighten the screws

8. Automatic feed: disassemble and install the chain on the fixed gear, press the clamping post and the fixing piece to install the chain in place

0.4v(square feed hopper type) please install the square hopper to the designated position and tighten the screws .

9. Install the motor pulley and fix the motor pulley on the motor shaft

10. Install the motor on the motor frame.

11. By adjusting the motor frame until the motor pulley and the host wheel are on the same plane(9ZR series machines are delivered for the whole machine, just install the power device)

12. Install the belt, adjust the position of the motor according to the tightness of the belt, fix the motor frame, install the machine cover

13. Install the speed control rod cap to the specified position, and tighten the upper casing screws

14. Safely turn on the power and observe whether the running direction of the machine wheel is consistent with the running direction marked on the machine. If the running direction is inconsistent, turn off the power ,rotate the two copper pieces at the motor connection point by 90 degrees (the wiring method remains unchanged)