Applications

Applications

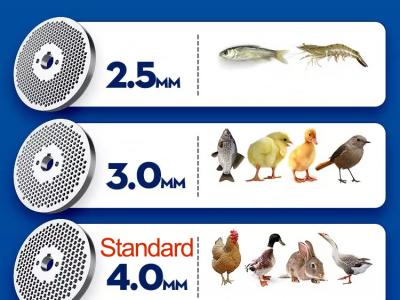

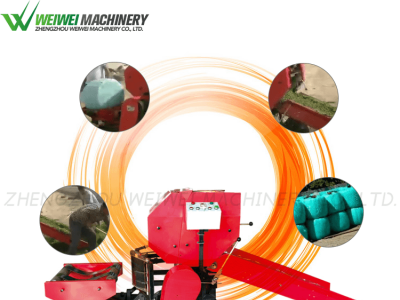

Automatic feeding hay straw kneading machine, 9zp series chaff cutter machines, the straw kneading crusher is mainly used for cutting corn stalk, bean stalk, cotton straw and other crop straw, pasturage grass and all kinds of grass, leaves, twigs, with hay straw kneading and crushing effect, cutter machine is suitable for different demand for animal breeding. for cattle, horse, rabbit, chicken, duck and other animal. Trustworthy products of large ranch and professional farmers .

Main features

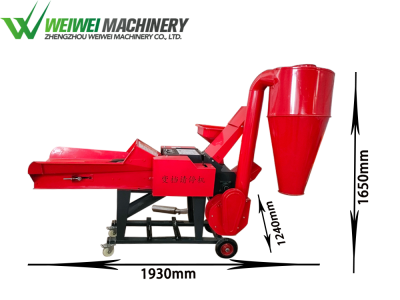

The machine used for cutting green (dry) corn stalks, straw and other crop stalks and forage. by the motor as a supporting power, the power transmission to the spindle, the other end of the spindle gear through the gear box, universal joints, etc. It will be passed through the speed of power transmission to the pressure roller, when the material get into be processed into the upper and lower pressure roller, Holding and at a certain rate into the cutting mechanism, the high-speed rotation of the cutter after cutting, the grass is thrown out of the machine by discharge port.

These plants can be cut as silage materials. Improve the utilization value of forage grass,the forage silage more fresh than green feed ,nutrition will not be reduced, and there is a sweet sour, after silage, can remove the odor and toxins, stimulate livestock appetite, increase feed intake, has a good role in promoting on the sheep's growth and development, and can be preserved for a long time, can reduce the parasitic disease

This machine has beautiful appearance, with full steel body, thick steel, coated by baking varnish craft, bright color, good durability, corrosion resistant, durable.

9ZP series products adopt automatic feeding device. The main frame, bracket and motor frame adopt combination of iron and steel structure, which enhance the stability of work, reduce noise too.

Cutting part adopt two,three, four, six groups plane oblique knife. Gear transmission enhances flexibility and service life, reduce grass resistance, increase the grass feed quantity, reduce noise and improve the production efficiency.

The kneading machine is made of all steel body with reasonable design, sophisticated production technology, operation safety and stability, and our guests can according to animal raised requirements, and different choices of power, provide product modification services for users.Meet the needs of users to the maximum extent

Our machines will be tested before they leave the factory to ensure the quality of service and ensure that all parts properly qualified,make sure it works properly。All parts of our studio are equipped with static balancing equipment. After debugging and installation then commissioning , the power balance adjustment ensures that the machine runs with low noise, stable machines and long service life.

1.Automatic feeding

and automatic feeding feeding table lengthened to protect the safety of personnel, simple operation, high safety coefficient. And the import feeding port is provided with a feeding protective cover, Beware of user operating errors cause harm to the body

2.Gear Box

The double gearbox unit can adjust the length of the material, the user can adjust according to their needs. The double transmission box structure can reduce labor force and reduce noise. And change the disadvantages of replacing the gear when adjusting the cutting length.

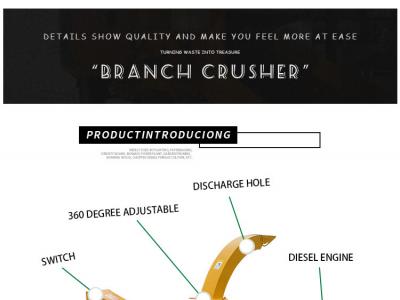

3.Discharge port

Heightening and lengthening the discharge port, and adding 360 adjustment function, which is convenient for users to collect the finished products.

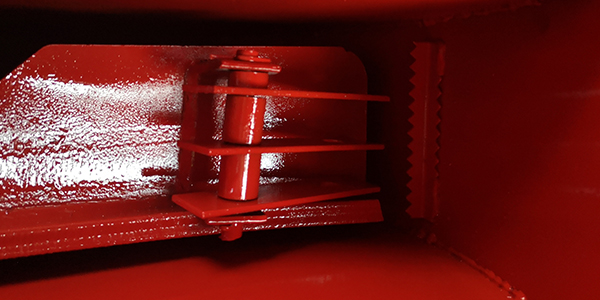

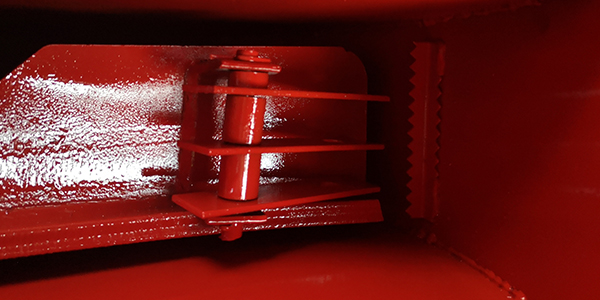

4.Hammer

Add hammer design, blade and hammer two-in-one, fusion cutting and crushing function,make the finished product be crushed more thoroughly