Application:

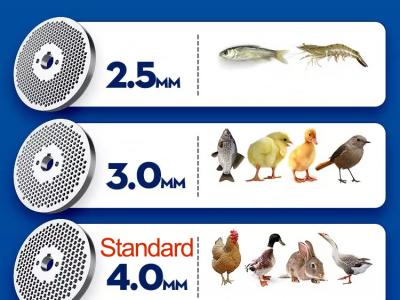

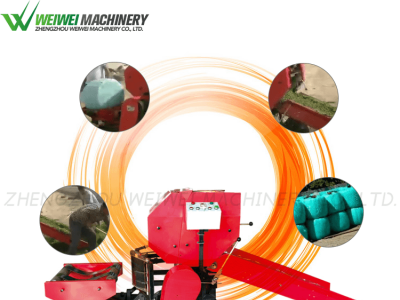

Animal feed cutting machine is used for rubbing corn straws, bean straws, cotton straws, pasture, many other crop straws. At the same time both the hay straw cutting, kneading and crushing effect, It is used for raising cattle , sheep, horses, rabbits, chickens, ducks and all kinds of animals,suitable for different needs of animal breeding .It is applicable for ranches and specialized feeding households. Weiwei agricultural machinery has set more than 200 sales outlets in more than 30 provinces, cities and municipalities. Our products are exported to Romina, America, Pakistan, Malaysia, Columbia,and other 40 countries., User feedback is good .

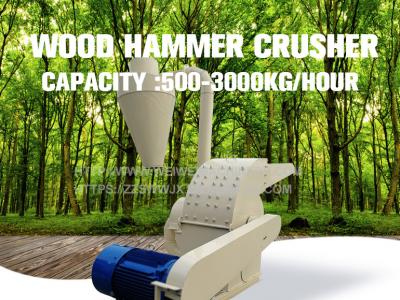

When the machine is running , the material is processed from the hopper into the crushing chamber, which is broken by the blow of the high-speed rotating working parts. At the same time change the the material movement direction.Because of the high speed rotation of working parts, the material layer is destroyed, the material is moving with the rotor. In this process, due to the repeated collision of forage or particles by working parts and the body friction, the the material is crushed to geometric diameter smaller than mesh diameter. Under the action of centrifugal force and air flow, crushed material through the sieve hole leak into the powder chamber, which can be discharged from outlet, the cutting forage can be sprayed from top discharge port.

This mill has beautiful appearance, with full steel body, thick steel, coated by baking varnish craft, bright color, good durability, corrosion resistant, durable .

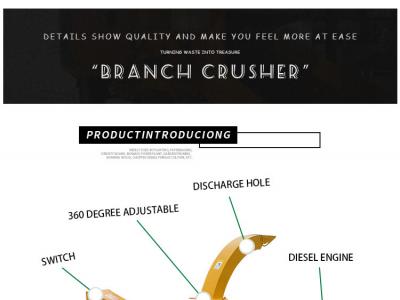

Design of grass cutting machine is unique and novel, high stability, safe work and low noise, long service life .

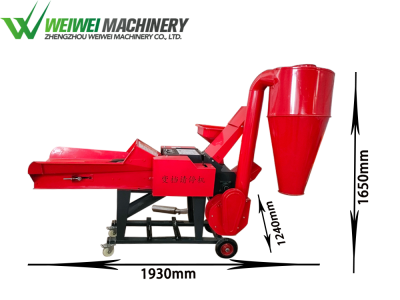

The crushing straw cutter is composed of an upper body , lower body ,rotor assembly, two feeding device, two discharging device ,screen mesh,crushing straw cutter room/grass pulverizing room,body frame,wheel and other parts, the body and the rotor assembly is an important part of the crushing chamber, the rotor assembly is the main working parts.

Our machines will be tested before they leave the factory to ensure the quality of service and ensure that all parts properly qualified,make sure it works properly。All parts of our studio are equipped with static balancing equipment. After debugging and installation then commissioning , the power balance adjustment ensures that the machine runs with low noise, stable machines and long service life.

1.Blades

65# manganese steel blade with double-sided serrated knife, Serrated blades available use on both sides , and when the side is worn out, the user can turn to replace the part, but can not change the blade position transformation, user can only turn to the original position, in order to ensure the static balance and stability.cutting and grinding the feed, improve the crushing rate at the same time.

2.Hammers

Multi-hammer design increases the degree of material fragmentation.When the saw tooth hammer wear without edges, the user can turn the hammer replacement, but can not replace each other , can only change to the original position, so as not to affect the rotor balance .

3.UC series bearings, can automatically adjust the balance, by high carbon steel precision processing, so it is easy to use and maintain.driving wheel with weight ballasting wheel ,increase the weight, inertia bigger, greatly improve the stability, saving power